Factory digital twin

Factory digital twin

Digital Twin

Simulation

LCA

Optimisation

Project overview: This project involved the design and implementation of a digital twin for a robotic battery sorting line. The system models both the physical layout and operational logic, enabling virtual testing, design iteration, and in-depth analysis of performance prior to any investment in real-world automation. The digital twin integrates robot arm simulations, detailed process flows, and predictive analysis for energy consumption, throughput, and staffing optimisation, delivering actionable insight for industrial automation and sustainable manufacturing.

- Developed a dynamic simulation environment using Quanser, accurately replicating the robot arm's behaviour and process logic on the virtual factory floor.

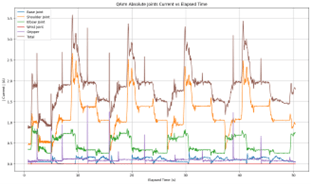

- Rigorously compared simulated performance metrics like cycle times, throughput rates, and energy consumption against real hardware data, validating the model and resolving discrepancies.

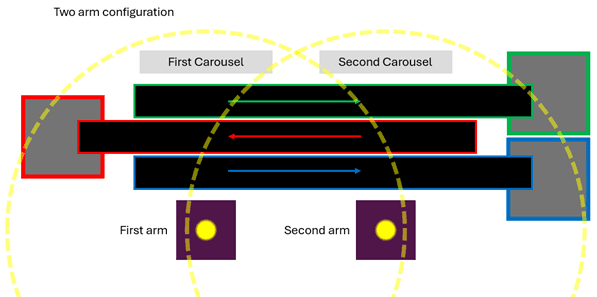

- Designed efficient facility layouts and conducted what-if scenarios (e.g., single vs. dual-arm setups, conveyor integration), optimising process flow and resource allocation.

- Conducted a detailed life cycle assessment (LCA) of the system's environmental impact, including the comparative influence of using recycled vs. virgin lithium-ion cell materials.

2 arm digital twin schematic

Technical Highlights:

- System Layout and Flow: Created both single- and dual-robot arm layouts with full conveyor integrations to maximise sorting throughput while minimising operator motion and power use.

- Simulation Validation: Benchmarked the digital twin by comparing its outcomes to those from a physical robot, uncovering and analysing a consistent underestimation of energy usage in simulation due to idealised motor modelling and absence of real-world inefficiencies.

- Staffing Optimisation: Used simulation data to identify the optimal technician-to-robot ratio, avoiding operator bottlenecks and supporting maximum automation utilisation.

- Environmental Impact: Executed a quantitative LCA comparing manufacturing impacts of battery packs using recycled versus virgin materials, visually presenting the reductions in climate, resource, and human health impacts when recycling is prioritised.

Arm power consumption data

Key Achievements:

- Enabled robust “what-if” analysis for process changes and scaling, supporting data-driven investment decisions for automation in recycling facilities.

- Delivered a statistically validated case for investing in closed-loop recycling infrastructure, especially for cobalt- and nickel-rich battery chemistries.

- Demonstrated real environmental and operational performance improvements—reducing global warming potential for key chemistries by over 20%, and resource depletion impacts by 73% through process optimisation and use of recycled materials.