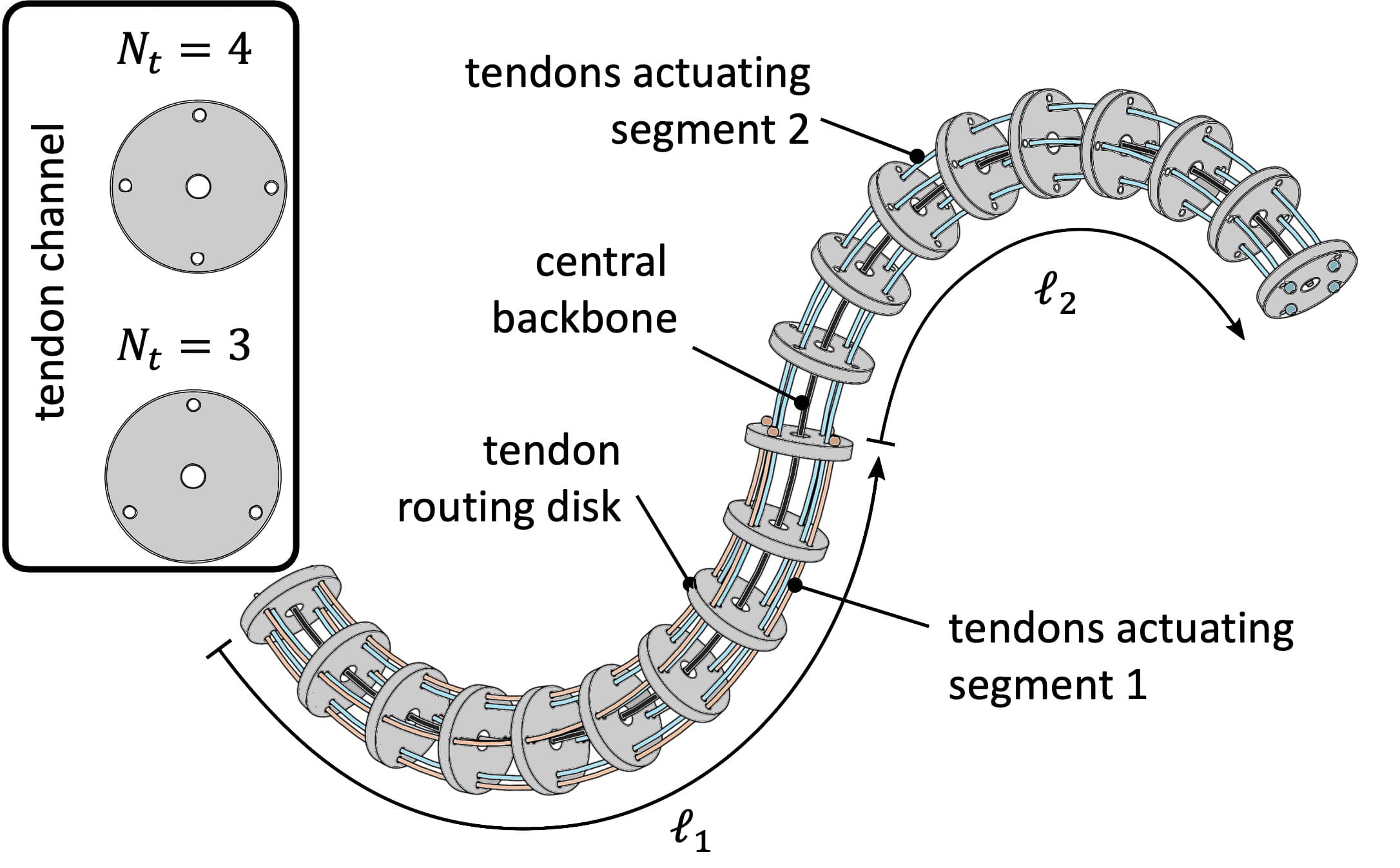

Tendon Driven Continuum Robots (TDCR)

Project overview: Facilitated the implementation of a closed-loop control system by adding custom IMUs spaced along the robotic arm. This involved substantial redesign of the existing CAD model to create precise mounting holes for the IMU boards and to provide pathways for power cables. Close collaboration with electronics engineers was necessary to select a lightweight board design that fit within the spatial constraints of the arm without compromising performance or adding excessive mass.

To improve the mechanical robustness and control accuracy of the arm, I conducted detailed analyses of the forces applied by the tendons on the arm’s central core. Using the mathematical model of the system, I obtained estimates for the maximum forces expected under operation. These results guided the setup of experimental evaluations on a Mecmesin force tester. I tested multiple design variants, experimenting with different material choices for 3D-printed components, three types of grub screws used for fastening, and the effects of surface coatings on the core. This experimental approach provided empirical data that informed design decisions, significantly reducing the need for iterative rebuilds during the arm’s final assembly.

The entire development process demanded a thorough understanding of both the mechanical behaviour and electronic integration of the arm, ensuring that the improved design could sustain the dynamic loads experienced during operation while maintaining precise positional control. I completed the project by producing a demonstration video showcasing the dexterity and capabilities of the final robotic arm, which was well received at a technical conference.