Floating waterwheel

As part of my MEng, I worked in a multidisciplinary team to design, build and test a floating waterwheel for use in low-flow irrigation canals, aiming to generate off-grid, sustainable power for rural farming communities. The design blocks most of the canal width to create a head difference, allowing both kinetic and gravitational potential energy to be extracted from flows that would normally lack the energy density for meaningful power generation. The prototype was built at half-scale, flat-packable for low-cost transport, and tested at the Chilworth flume facility. Experiments validated the design’s ability to deliver significantly more power than the available kinetic energy alone would suggest, confirming its potential for real-world use.

Mechanical design and rapid prototyping: Materials and structural decisions were made to balance performance, cost and manufacturability. Aluminium blade arms were selected for their corrosion resistance, low weight and ease of machining, while vertical stiffeners were added to the aluminium frame to reduce flex under load. A hollow 50 mm aluminium shaft was sourced and precision cut to fit available bearings. Custom components were developed and iterated quickly using a personal 3D printer, which allowed same-day testing of solutions. This included a reinforced, high-friction shaft clamp to eliminate drivetrain slippage, adjustable mounts for sensors, and quick-change magnet holders for RPM measurement. These rapid iterations helped keep testing on schedule and allowed small design issues to be resolved before they became bigger problems.

Electronics and data handling: The prototype’s electronics were designed to be flexible and easy to adapt as testing evolved. Core components included an Arduino Nano ESP32 for wireless connectivity, a high-accuracy power sensor, an IMU, and a waterproof hall-effect sensor for rotational speed. A unified codebase handled data from all sensors, with a JSON-based logging format enabling simple addition or removal of data points without breaking analysis scripts. Wireless live plotting allowed the team to spot anomalies in real time; for example, detecting drivetrain slip from a voltage drop before it was visible in the wheel’s motion.

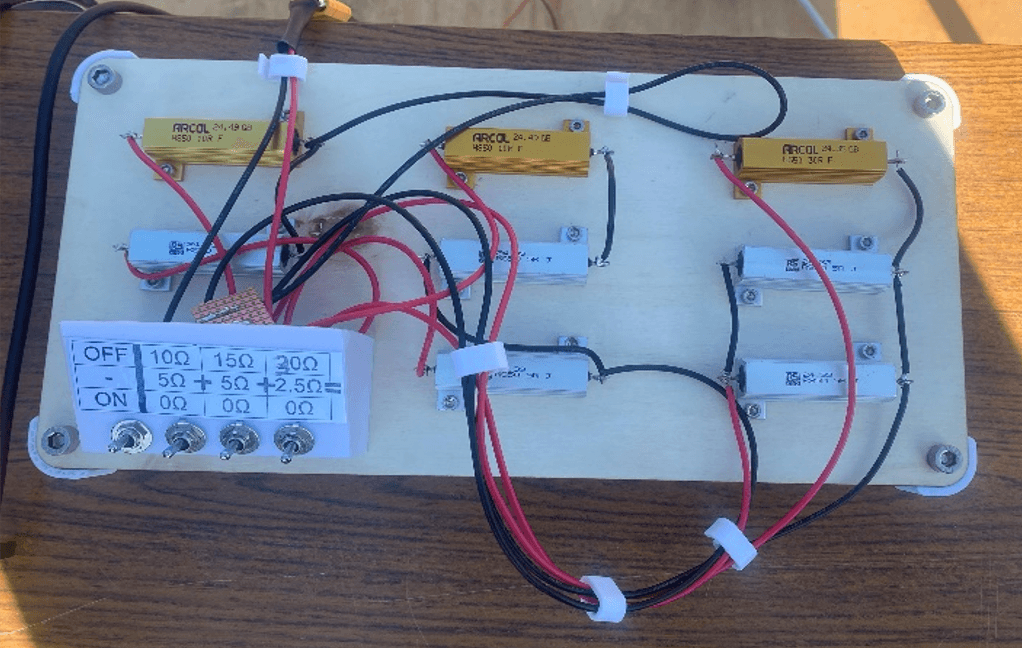

Testing and problem-solving: Testing at the flume facility demanded quick thinking to keep momentum. When the original resistor switchboard failed, a replacement was designed and built within 24 hours. Modifications to improve drivetrain grip, refinements to pontoon design, and custom wire-routing clips all contributed to a smooth and reliable testing process. The ability to diagnose and implement fixes rapidly meant the prototype could be tested in a wide range of configurations within the project’s tight schedule.